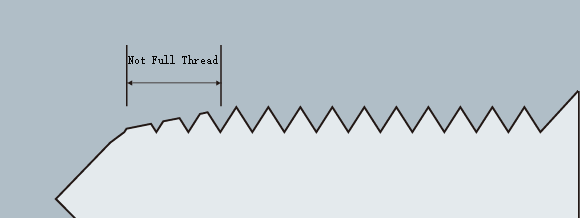

1. During threaded blind hole processing, incomplete threads appeared.

To reduce incomplete threads, using a thread mill or tap with a shorter cutting taper length is key.

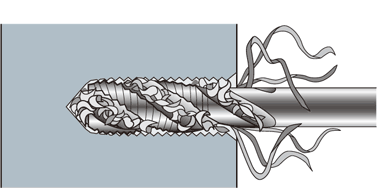

2. How to process the bottom hole of the extrusion tap?

Use carbide drill bits (smooth-edged drill bits with rollers, etc.) that are more precise than traditional high-speed steel drill bits.

For small-diameter holes, it is recommended to use a high-precision drill bit with a drill bit diameter that is accurate to a hundredth.

After using a drill for bottom hole machining, it is very effective to use an end mill for contouring and boring cutting.

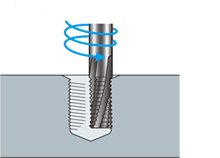

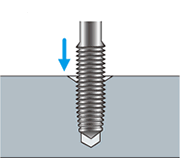

3. Processing small diameter threaded holes

Using a small-diameter thread milling cutter can break chips into fine pieces, enabling stable small-diameter threaded hole machining.

Use extrusion taps for plastic processing.

Anyang Rarlong Machinery Co., Ltd.

Contact:Mr. Yang Poping

Tel:+86-372-2517069

Phone:+86 13803722027 Mobile/Wechat

E-mail:sales@rarlongmachinery.com

Add:South Guangming Road,Anyang City,Henan Province,China