What is spinning technology?

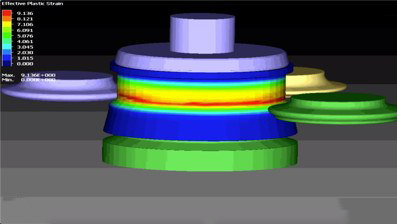

According to the plastic characteristics of the material, the blank is clamped on the mandrel and rotated accordingly. Reasonable spinning process parameters are selected. The spinning tool (wheel or other special-shaped parts) and the mandrel are fed relatively continuously, and the workpiece is processed in turn. An advanced plastic processing method that applies deformation pressure to a very small part of the blank to pressurize the blank and produce continuous point-by-point deformation to gradually shape the workpiece.

Process features: low cost, low power consumption, and improved product strength.

1) During the spinning process, the rotating wheel exerts pressure on the blank point by point, with a small contact area. The unit pressure can reach more than 250-350 kgf/mm2. For processing high-strength and difficult-to-deform materials, the total deformation force required is small. Thus greatly reducing power consumption.

2) Under the action of three-dimensional deformation force, the metal grains of the blank are displaced along the slip surface in the deformation zone. The direction of each slip layer on the slip surface is consistent with the deformation direction. Therefore, the metal fibers remain continuous and intact. Due to the strain in the metal lattice structure, the strength, hardness, tensile strength, and yield limit of the spun products are increased.

3) Powerful spinning can make the products achieve higher dimensional accuracy and surface finish. During the spinning process, the rotating wheel not only has a rolling effect on the metal being spun, but also has a smoothing effect, so the surface finish of the product is high.

4) Spin forming can be performed under normal temperature and heating conditions of the metal.

5) The range of products is very wide. Depending on the capabilities of the spinning machine, it can produce large-diameter thin-walled pipes, special pipes, variable-section pipes, and almost all rotary parts with spherical, hemispherical, elliptical, curved generatrix shapes and steps and varying wall thicknesses.

7) There are many sources of blanks. Hollow stamping parts, extruded parts, castings, welding parts, machined forgings and rolled parts, and circular plates can be used as blanks. It can spin non-ferrous metals, ferrous metals, and materials containing titanium, molybdenum, Tungsten, tantalum, and niobium are alloy metals that are difficult to deform.

8) The spinning process also plays the role of automatic inspection of products. It can effectively improve defects such as cracks and blisters in materials. For example, in the rim spinning of cast aluminum wheels, the removal rate of blisters after spinning is close to 100%.

Anyang Rarlong Machinery Co., Ltd.

Contact:Mr. Yang Poping

Tel:+86-372-2517069

Phone:+86 13803722027 Mobile/Wechat

E-mail:sales@rarlongmachinery.com

Add:South Guangming Road,Anyang City,Henan Province,China