Two kinds of Manufacturing Methods for Steel Wheels

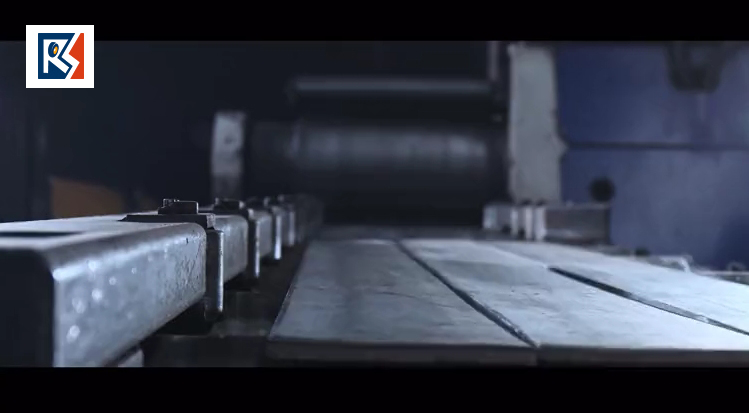

Method 1: Section Steel or Hot Rolled Steel Plate Coiling

Bend section steel or steel plate into a circle, close up and weld, compress, expand, smooth the weld, re-compress and punch the valve hole.

Disadvantages:There are solder joints at the joints.The requirements for equipment processing capacity are not very high, but the requirements for welding technology are high.

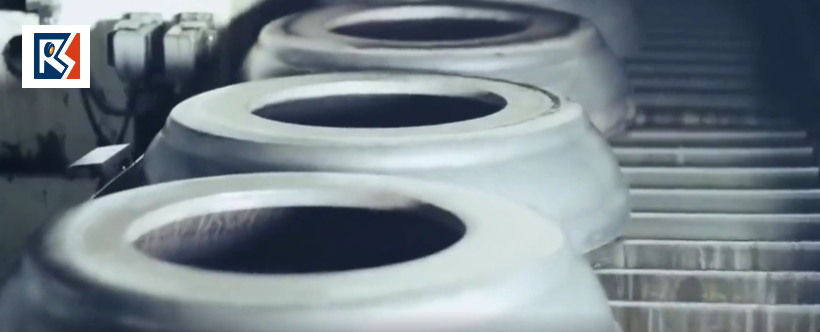

Method 2: Hot Pressing Forming of Steel Plate

Steel plate is cut into a circular ring, heated in a heating furnace, and pressed into wheel rim by oil press through forming mould.

Advantage: No welding points. Production process and equipment are more advanced. Disadvantages: The equipment investment cost is high.

Rarlong Machinery, professional manufacturer and supplier for OTR steel wheel rim, OTR wheel rim, construction wheel rim, agricultural wheel rim, mining wheel rim, heavy duty wheel and wheel rim components.

Anyang Rarlong Machinery Co., Ltd.

Contact:Mr. Yang Poping

Tel:+86-372-2517069

Phone:+86 13803722027 Mobile/Wechat

E-mail:sales@rarlongmachinery.com

Add:South Guangming Road,Anyang City,Henan Province,China